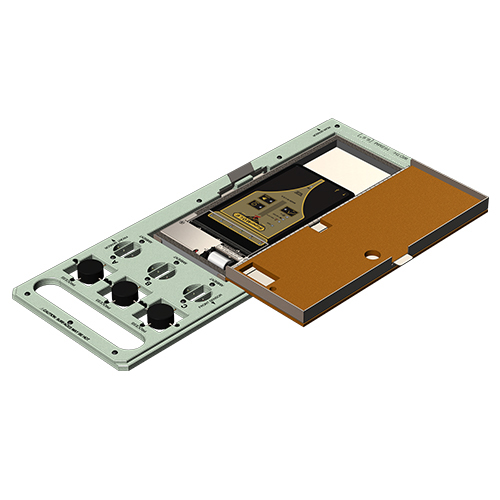

Three high mass pucks measure the effect of convection to drive heat evenly into a product. Each oven zone reports a Process Delta to verify convection consistency for SPC. This detects a failed fan, restricted vent or incorrect oven convection setting.

Three exposed fast response thermocouples average the center 70% of the measured air temperature in each zone to verify consistency for SPC. This detects a failing heater or wrong oven setting. The NL 2+ pallet design offers added protection from accidental damage.

Front & Rear Speed Sensors define process origin and conveyor speed with rail-mounted ‘Start’ magnet. Belt speed verified for consistency (SPC).Detects the wrong oven setting or maintenance requirement.

There is an LED porthole on the top of the barrier cover that illuminates when the OvenRIDER NL 2+ detects zone boundary. This LED is powered by a replaceable 3.6 volt ½ AA lithium battery.

The Rider LED Indicates when SuperM.O.L.E.™ Gold 2 is connected to a OvenRIDER NL 2+ test pallet. And when connected to a M.O.L.E.® EV6, a “RIDER“ symbol appears on the display. This also automatically sets the M.O.L.E.’s configuration.

This barrier also is equipped with external insulation on the top and bottom, which provides the extra thermal protection needed for Lead-Free processes. This barrier is lowered 0.685” [17.40mm] into the plane of the pallet for extra oven clearance.

PHYSICAL:

| Size: | Length: 452mm (17.75 in) Thickness: 31.75mm (1.25 in) Width: 167mm (6.6 in), 305mm (12 in) ,458mm (18 in) |

| Weight (僅OvenRIDER® NL 2+): | 168mm (6.6 in) – 1.74 kg (3.84 lbs) 305mm (12 in) – 2.81 kg (6.19 lbs) 457mm (18 in) – 3.54 kg (7.8 lbs) |

| Max working temp(Pallet): | 300℃(572°F ) |

| Max working temp(Thermal Barrier

): | 200°C (392°F),lasting 9.5 mins/ 230°C (446°F), 8 mins |

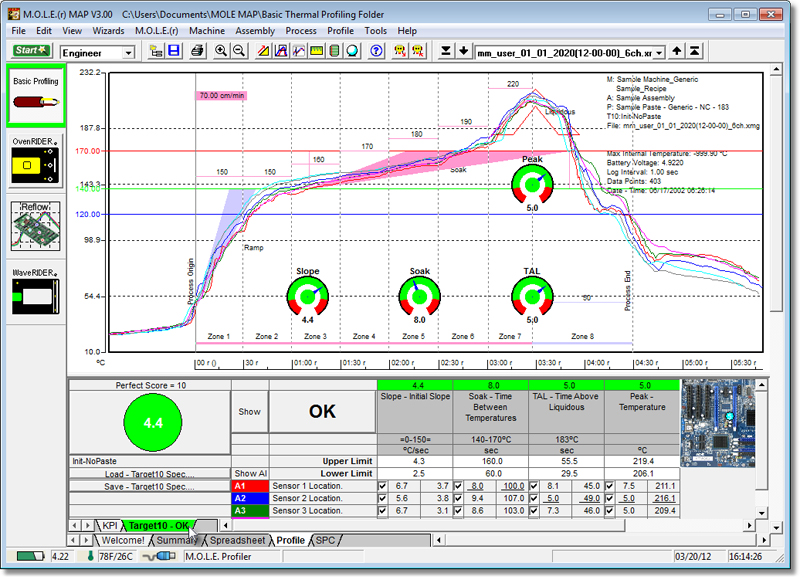

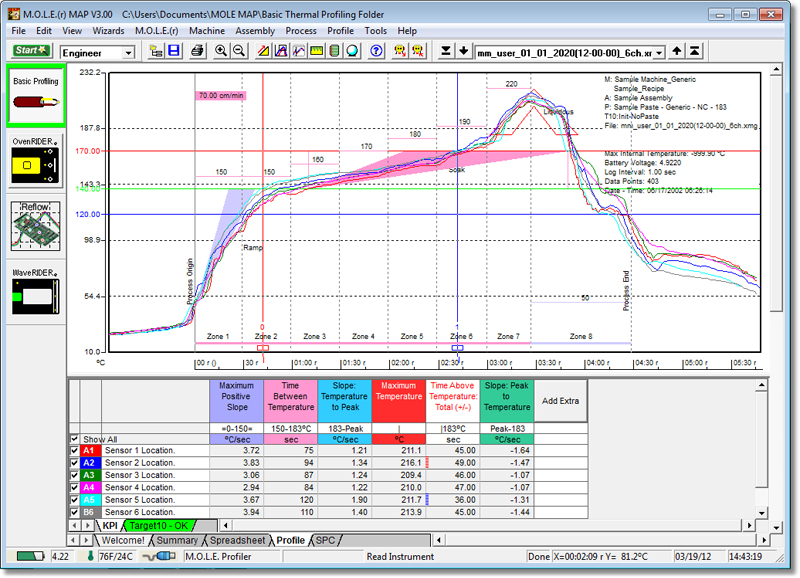

Software

OvenRider NL2+

Data Collection

Equipped with thermal profiler